Auch verfügbar auf Deutsch

At the WATCHTIME (Exhibiton) in Düsseldorf, Germany, I could watch Jochen Benzinger at his work for the first time. Very impressive. In the following interview you will find everything worth knowing about Jochen Benzinger and his watches! Have fun reading!

1. Your watches are characterised by the fact that they are made with an old, forgotten craft,on a so-called engine turning or guilloché machine. What exactly is the craftsmanship of guilloché and how and where can you learn such a thing?

Engine-turning is an old craftsmanship, which has its origin in the art of ornamental turning. From the 16th to the 18th century, almost the entire high aristocracy of Europe was trained in this craft, whereby ornamental turning in particular was popular, as it symbolized the world’s view of that time better than anything else: everything should rotate around the sovereign! In this respect, guilloché work is still referred to today as the “royal craft”.

Engine turning actually is a specific technique of engraving. The difference: when engine turning, it’s the workpiece that rotates, when engraving it’s the engraver making the necessary movement. Unfortunately, this old craft no longer exists in Germany as a teaching profession since the 1960s. Gradually, it has been assigned to the job description of engravers and is only taught in a rudimentary way today – and just when a corresponding machine is available! This also has to do with the fact, that in the past pieces of jewellery that are now simply out of fashion, often were guillochéd. In fact, this technique can today be found in the field of watches.

Strictly speaking, a guilloché machine is not a machine as one would commonly define it. It is rather a tool that is operated manually. It consists of a spring-mounted rosette stock that is driven by the guillocheur through a crank. The pattern rosettes are run off by means of a “touche”, whereby the pattern is transferred to the workpiece clamped at the front. The cutting of the pattern usually is carried out from the outside to the inside, i.e. from the largest to the smallest diameter. After each round, the diameter must therefore be reduced. Depending on the offset of the rosettes, a wide variety of patterns is thus created, such as a classical barley, a moirée or a ray guilloche. The variety of patterns is almost infinite and originates from the creativity of the guillocheur.

2. Besides engine turning you also skeletonize and engrave. You design individual pieces and collections and even refine them? That is quite an extensive work!

Yes, I think you can undoubtedly call it extensive with a clear conscience. But maybe also extremely varied! We see every unique piece we build as a new project of its own, the implementation of which often only arises during construction. Of course you have a plan, a course of action that is determined solely by the technology. In other words: every clockwork has given factors that cannot be changed. Skeletonizing, engraving and engine turning are only refinement techniques, which must not affect the functioning of the movement! But we still carry these out completely by hand! Therefore we are also very flexible. And, of course, the customers’ wishes are always on first position in all projects. Sometimes I change my original plan in the middle of a project, or the customer himself suddenly has an idea… We try to take this into account.

Besides my own watches, we also make special series for other well-known watch companies. Some have us made hand-cut dials, others use hand-skeletonized movements.

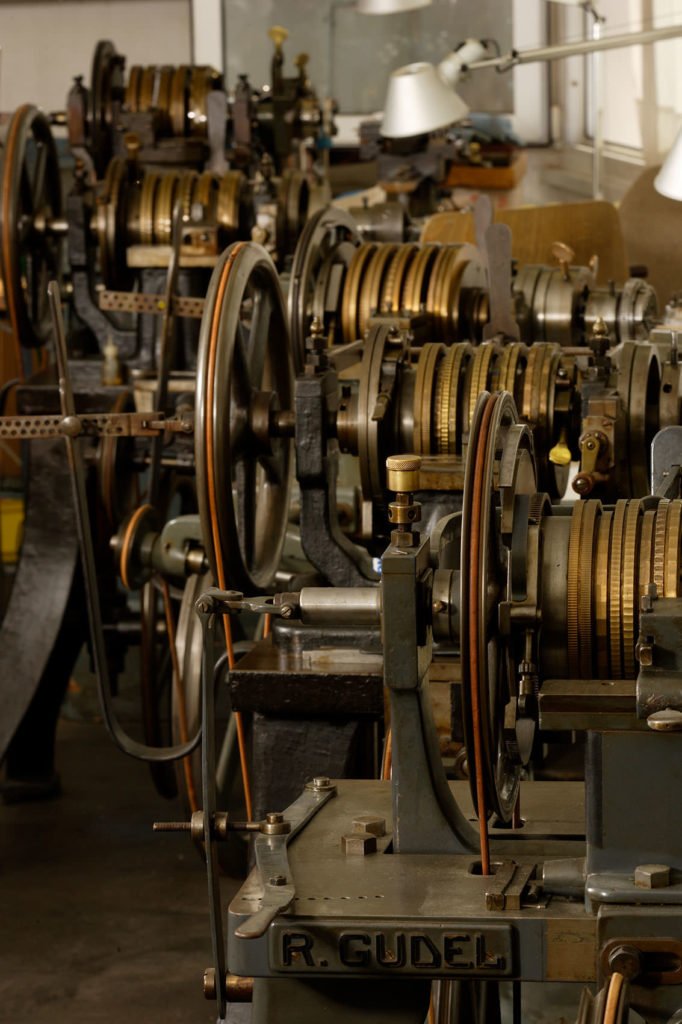

3. I watched you at the Watchtime (Exhibiton) with fascination while working with the guilloché machine. Where do you find such machines? Surely nobody makes them anymore…

That’s correct. These machines are hardly manufactured in these days, since almost nobody can operate them anymore. Therefore they are now very sought-after collector’s items! Especially of course the “old” machines, which are a work of art in themselves. Most of our machines are over 100 years old, but still in daily use. The newer, the simpler the machines are in appearance. However, nothing has changed in terms of how they work, i.e. the manual operation. The only electrical thing is the light! We were fortunate to have taken over many of these machines from Pforzheim jewellery companies when they ceased operations or modernised their production.

4. Today we know you as a successful watchmaker. But how (exactly) did this come to be/happen? When you are young, you usually don’t decide to become a watchmaker, learn old craftsmanship and start your own manufactory. Have you always had this passion for watches and craftsmanship?

Let’s put it this way: I never wanted to be a fireman! No, seriously… In the past, my greatest wish was to become a dentist – so I have always been interested in sophisticated craftsmanship! Added to this was my talent for drawing and design, so that in the end I became a gold engraver after all. After my apprenticeship, which I completed with several awards, I was able to take over a small business, at that time even with a special permit from the Chamber of Crafts, because I only made my master craftsman’s diploma while working. In the beginning the main focus of my work was more on jewellery, but that – and the prevailing taste – changed in the course of time, as I’ve mentioned before. At some point I did not only want to refine the watches of others, but also to build my own timepieces – and my creative handicraft brings with it that these are mainly unique pieces, which we build on customer’s request. Over the years we have grown with our projects and have brought the manufactory idea to life step by step.

5. What do you think made your watches so well known in certain circles?

Just as every car bears the signature of a particular designer, our watches have something unique about them, due to the techniques used. We normally work with standard movements, but they are no longer recognizable when after having gone through our hands… We are the only ones in Germany who supply both technical modifications and creative design of the movements from one single source. My work is so distinctive in its execution that you can easily recognize it by now. And of course, the high proportion of manual work thus gives me enormous leeway!

6. Founding a successful watch manufactory means a lot of work, passion, but also setbacks. Were there moments when you no longer believed in your dream?

No, never. If you don’t believe in yourself, you should remain an employee or not take the step to self-employment. If something doesn’t go as planned, we see it as a challenge.

7. In terms of the design by Jochen Benzinger – do you have any particular role models? What do you base your design and material selection on?

Certainly every watchmaker tries to find his own style. And for us, that is not difficult at all! In general, our watches have a very high recognition value – and not only among experts and colleagues! But of course I have role models whom I admire very much, e.g. Abraham Louis Breguet – probably one of the most famous watchmakers ever! – and in his tradition we still cut and frost our handmade dials today.

8. Can you still remember the first watch you made? If so, would you like to describe it to us and draw a conclusion as to whether some kind of “evolution” has taken place until today in terms of design or manufacture?

To be honest, I don’t remember exactly what my first self-made watch looked like… The transition from watches finished for customers to the first BENZINGER watch was somehow smooth. The beginnings were perhaps still a bit undistinguished, but of course one keeps on evolving in the course of time, I became more courageous and also tried out various things – not all ideas survived or were further developed. However, I am very fortunate to work with outstanding colleagues of the jewellery and watch industry, and in this respect one can certainly speak of “evolution”. Today, of course, it is easier for us to assess what will look really good or what is technically feasible.

9. The skeleton watches in particular clearly show how fine and precise your craft is. That is incredibly impressive! Could you describe to us how exactly the work process runs from order to the idea to the production?

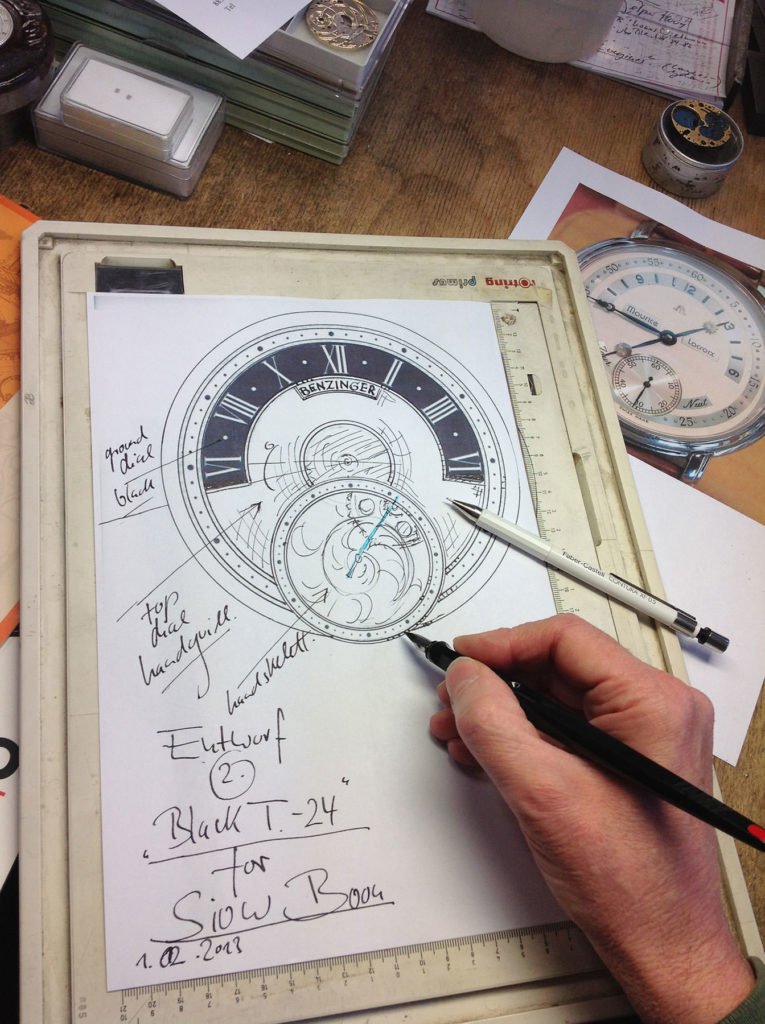

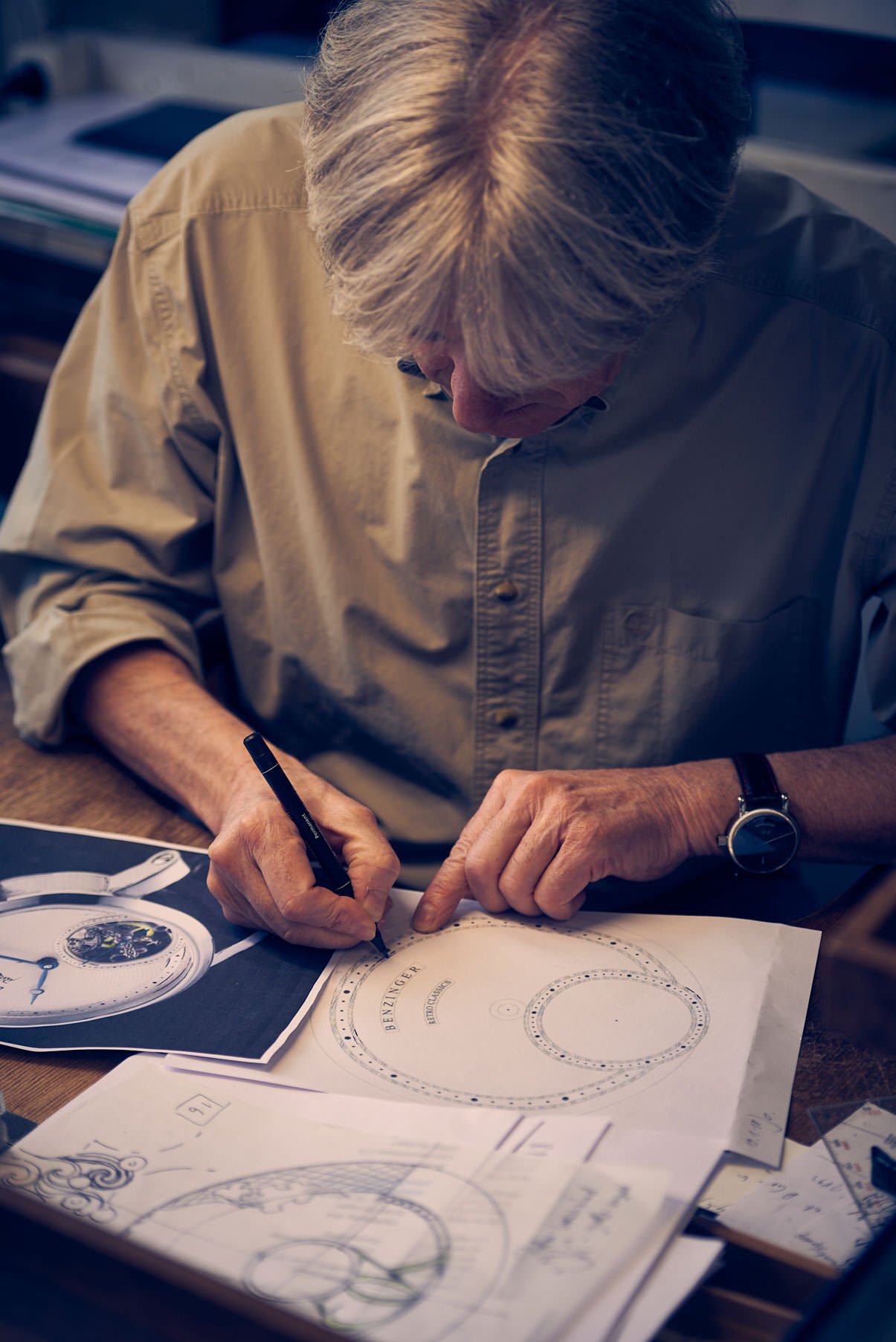

First of all, two basic things have to be clarified with the customer: is it to be a full skeleton watch, i.e. a completely skeletonized movement without a dial, or a three-quarter skeleton where at least parts of the dial still remain? And how should the design be: rather straightforward, technical or playful ornamental? In some cases, we make sketches – by hand, of course! – that give a first impression. And then it starts! First the movement is disassembled into all its individual parts, which are then worked on one after the other. In the meantime, we have already refined so many movements that you know exactly what can and cannot be removed.

I sketch with a pencil where I want to make an engraving, i.e. where material needs to stay. Bearing jewels also have to be considered, the rest is then cut away with a goldsmith’s saw – in the style the customer wants. We can also take special requests into account, such as inserting the customer’s initials to the movement. The goldsmith then has to finish various parts of the movement by rhodium- /gold plating or PVD-coating the parts, so that they can be highlighted or emphasized in color. The watchmaker must then reassemble the complete movement and check that everything runs smoothly. This procedure applies not only to our skeleton watches, but to all models.

10. How long does it approximately take to produce a single piece?

On average, we need about 100 hours to build a unique piece. But that is only the time we need for our work – guilloché, engraving and skeletonizing. In general, however, the customer can assume a delivery time of about 3 months from the time of ordering. But of course there are also projects that take much longer… Some customers have very unusual wishes concerning a special movement that we are happy to search for and sometimes we go to auctions to buy a corresponding piece.

11. Who are your customers?

We manufacture most of our unique pieces for private customers worldwide. We also do contract work for well-known companies in the jewellery and watch industry.

12. How do you ensure the customer is satisfied in the end with the way you have realized his ideas?

One of the most important thing when taking on an order is to exactly define with the customer what he wants and how the watch should look like in the end. Many of them already have a very clear ideas and we show them what is possible and what’s not. Some of them actually find it most difficult to decide on the basic type of watch itself. Do I prefer a technical re-design? Or is my main focus on a skeleton watch that reveals its innermost self to me? Of course, we can’t make that decision for anyone. While building the watch, we often provide our customers with pictures of the progress made, so that certain things can be changed if necessary. Like this we make sure, that we finally end up with something that wasn’t intended. After having sent the watch to the customer in a nice box, we often get an e-mail right away with a corresponding reaction… The satisfaction and enthusiasm of the recipient is my greatest incentive!

13. Have you got an explanation how an old, forgotten craft could become so popular again? That seems to be a clear trend.

We too can confirm this trend. It very much looks like people are returning to old traditions. Times when everyone wanted to have what the neighbour had as well, are gone! And for many people a status symbol no longer has the same meaning as it did a few years ago. Nowadays, people appreciate much more that someone else cared about their ideas and put them into practice. As opposed to a “luxury” or brand watch, the customer then has a manufactured product, literally “manufactum – made by hand”, a unique piece for himself and according to his ideas, not an “off-the-shelf” movement that is perhaps already available in 100,000 pieces. Furthermore, if a story can be told about the creation of the watch – e.g. about the fact that old machines and an old handicraft were used to build this watch and that this could have been discovered during a visit to our workshop – a customer appreciates this even more!

14. What was the most unusual order you have ever accepted?

As you know, we have customers all over the world. Among other things, we often receive inquiries from the United States, and I would like to set up one of our most unusual projects there… A customer had us built a minute repeater in a platinum case – a complex but exciting story! His son, being 12 years old at that time, was obviously quite thrilled by the thought that a watch had been built especially for his father. And so his dad probably wanted to do him something good and had us built a watch for his son, too. The only specification: it should have something to do with science fiction! And so we designed “Area 51” for him…

15. Are you thinking of preserving the knowledge of these old techniques and passing it on to the next generation? It must be incredibly difficult to find young people who willingly want to accept this inheritance.

This is where we take up question 13… It is not only older people who, in terms of traditions perhaps even feel taken back to their own youth. Especially for young people who grew up with computers and automation and the resulting egalitarianism, it is important to set themselves apart from their friends, to seek the individual and to be something special. At trade fairs and exhibitions, where we always bring one of our old engine turning machines, we often meet young people who are extremely keen to know what we do and how it works! In Pforzheim, the jewellery and watchmaking town, we also have a school for goldsmiths with an affiliated watchmaking school. We get a lot of inquiries regarding an internship. The curiosity and the joy of creative work are just great! Some of them stay with us beyond the duration of the internship and try out new things in private. In this respect, I hope that this craft will also find its way into the future – if not as an apprenticeship, but nevertheless as a technique worth preserving.

Gallery Jochen Benzinger Interview

Jochen Benzinger you will find here:

http://www.jochenbenzinger.de/

https://www.instagram.com/benzingerwatches/